Gecko Shelf (2019)

Counter space is limited in my studio kitchen and this lack of space becomes an issue when cooking and/or preparing food. I envisioned a working surface that could be easily mounted and repositioned onto the side of the counter or wall when needed, in effect increasing the usable area of the kitchen. The mechanism was inspired by the suction cups used for moving heavy tiles or large glass panes.

Use & Operation

When the shelf is moved to its horizontal position the linkage translates that motion to the shaft of the suction cup - pulling the cup shaft forward and creating suction. Conversely, moving the board to its vertical position pushes the cup back and releases the suction.

Use Cases

Food Preparation & Cooking

Testing out the Gecko Shelf prototype on my kitchen window - chopping up some finger chili peppers for a spicy lunch.

Shelving

A secondary application for the Gecko Shelf is temporary shelving. The shelf can be attached to glass or any flat/non-porous surface.

Design Process

Proof-of-concept

3-D printed v.1 suction bracket prototype. This prototype served as an initial test to confirm the functionality of the mechanism and its performance under load.

Sketch Exploration

Exploration of linkage designs for the suction bracket through sketching. These concepts were recreated with paper sketch models to further understand the mechanics of the linkage.

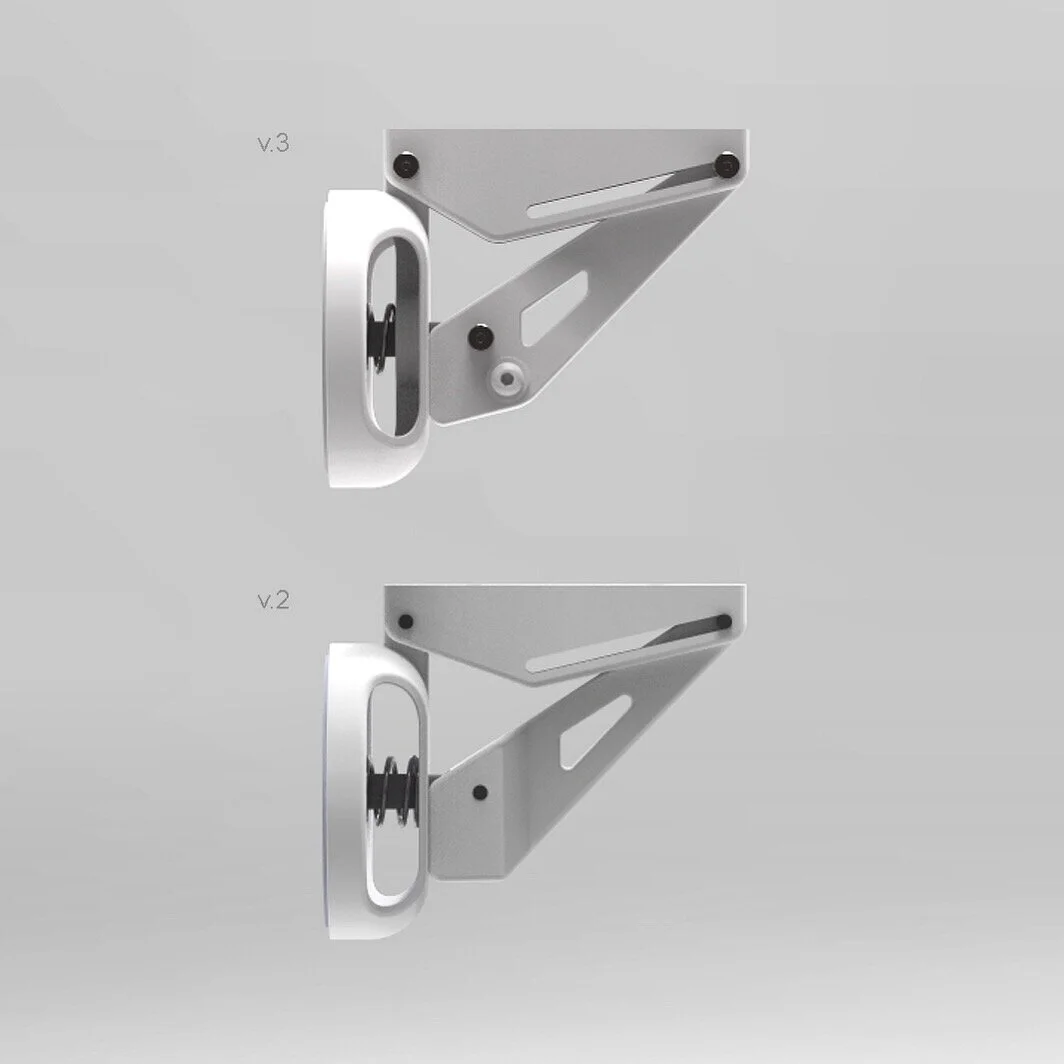

V.2 Bracket Design

I chose the best design from the linkages explored in the sketch models and translated it into CAD - refining the motion and geometry of the linkage, and incorporating the assembly hardware.

FEA Analysis

Stress visualization of the v.3 plunger arm. Darker areas represent regions of low mechanical stress, whereas lighter areas represent concentrations of high stress resulting from the simulated load.

Structural Refinement

Based on the FEA results, the plunger arm was redesigned to reduce stress concentrations and a hole was added to accommodate the horizontal rod that links the left and right bracket. Reinforcing ribs were also added to the inside of the plunger shell to increase its rigidity.

Final Assembly

Exploded view of the complete shelf assembly. Further structural refinements were made to the bracket design, hardware was sourced, and the shelf was assembled. For future development, I’m interested in exploring means of securing the shelf to irregular vertical surfaces and simplifying the mechanics.